Multiplast demonstrates its expertise through the production of plastic films and sheets of polyethylene that could be customised according to its clients’ needs. The French manufacturer guarantees optimised lead times.

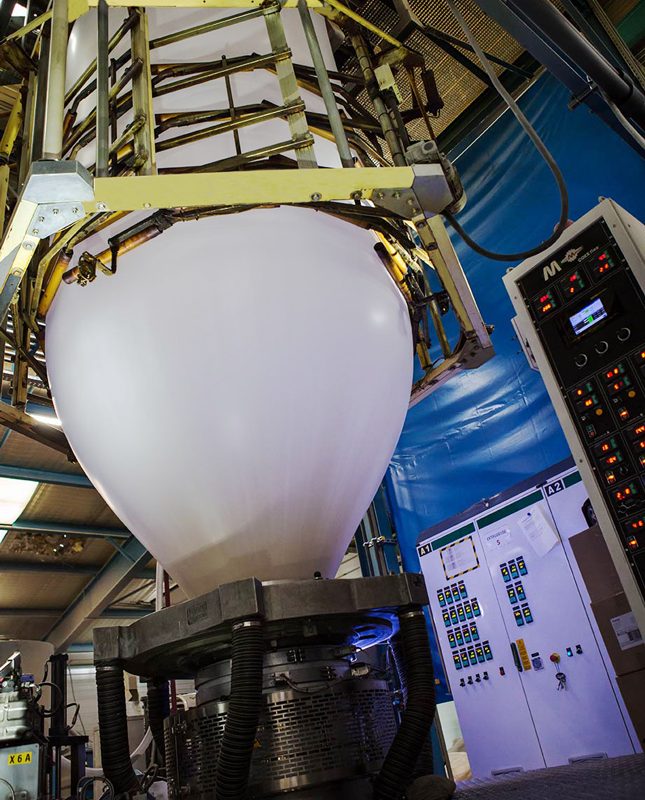

These high-quality products incorporate the three-layer LDPE technology, which makes them particularly sturdy.

With full control over the entire production chain, the plastics manufacturer also runs tensile tests to verify the finished product’s stretching properties. The selection and compositional analysis of plastic pellets is a decisive quality measure prior to production.

Multiplast’s customised film extrusion offering is available in widths from 1 to 6 metres and thicknesses of between 5 and 200 microns. The raw materials used come from recycling. The products themselves are recyclable.

With a storage capacity of 15,000 m² and a delivery time from five days, the manufacturer produces continuously 24/7 thanks to a fully automated process.

Beyond the production itself, Multiplast plays a role of partner and advisor, supporting its clients from the offering definition to the sales. Combining technical expertise to marketing and commercial approach, Multiplast builds a customised offering together with the selling tools (merchandising recommendations,…)

Multiplast’s custom extrusion:

Custom plastic films and sheets offering.

Optimised lead time from development to production.

3-layer LDPE.

Width: 1-6 metres.

Thickness: 5-200 microns.

Recycled materials

Storage: 15,000 m².

Delivery: from 5 days.

Production: continuous.

For our customers’ brands (private label)

Industrial and technical & commercial expertise